The steel industry is rapidly changing due to frequent business process transformations, cost reduction initiatives and simultaneous innovation. IT divisions in the industry are facing multiple challenges in acquiring diverse technology skill sets, training of IT staff, retaining experienced ones and replacing aging IT professionals. Additionally, growing merger and acquisition activity is making the global IT and automation landscape more complex and unmanageable. How can this progressively complex issue be addressed?

Need to Outsource

The steel industry has undergone fundamental changes in terms of outsourcing of Application Development and Maintenance (ADM) of their IT and automation systems in recent times. The key factors influencing the transition are:

As the need for outsourcing IT systems grows, global steel players are actively looking to give out the maintenance work to global IT vendors.

IT and automation landscape in core manufacturing is domain-rich, full of legacy and proprietary systems. The enterprise and manufacturing systems are also closely integrated. Outsourcing of IT services, therefore, needs careful evaluation to minimize risks.

Smaller steel companies outsource to local vendors, whereas the larger ones outsource to the global vendors. The steel sector is primarily involved in large volume sales and fewer number of sales transactions. They are usually not directly involved with individual end-user community. That is why not all new technologies under SMAC (Social, Mobile, Analytics and Cloud services) that have penetrated areas of business-to-customer, have an impact on the steel industry. Analytics and cloud, however, have impacted the industry in a big way and that requires new technology skill sets.

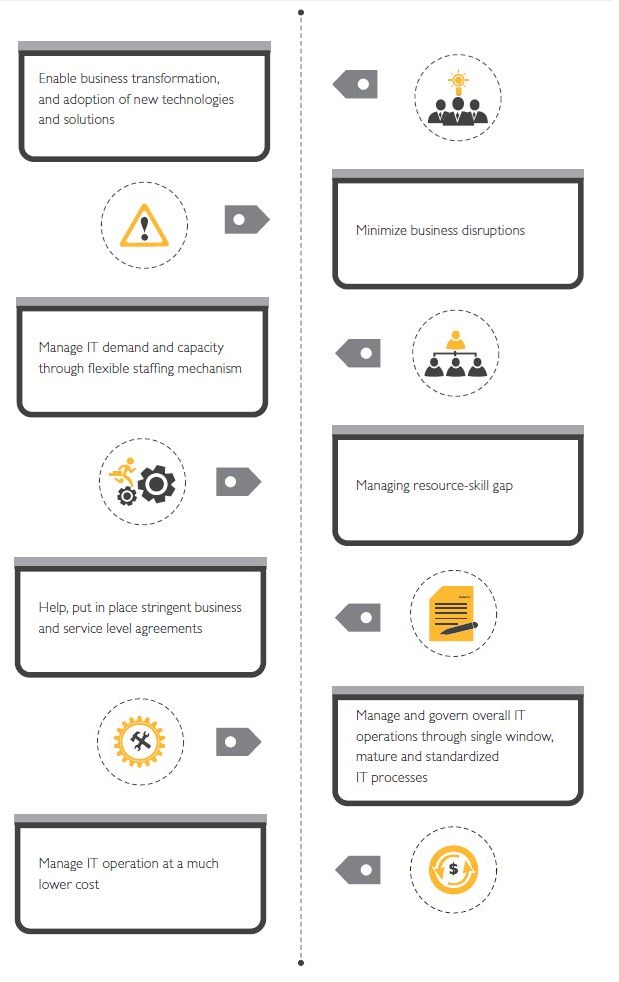

There is, therefore, a need for steel companies to go for large scale outsourcing. Some of the reasons to take the outsourcing route are:

Reduction in IT expenditure and streamlining:

With rapid changes in business functions, a technologically adept and well-equipped IT team would be a valuable asset to today’s CIOs. This can help streamline business processes, enhance manufacturing capabilities, thereby reducing costs.

Business agility and real-time changes:

Everyday there is a change in demand for steel, raw material prices, steel prices, scheduling etc., which need to be accounted for when the system is designed. Any change in the integrated system has a large scale impact across the business and manufacturing systems. External support can help ensure as-required support for the industry.

M&A and globalization:

Due to growing M&A activity, there is a need to harmonize business processes, de-centralize manufacturing, and centralize information flow. There is also a need to have a global supply chain view, internal and external supply chain optimization, optimal inventory management, maximize profitability and ensure smooth cash flow. All this necessitates taking the outsourcing route.

Rationalization, harmonization and transformation:

The existence of complex legacy applications, established ERP and MES packages on diverse technology platforms make transformation difficult, time consuming and risky. With faster changes in business landscape and simultaneous reduction in IT budgets, there is a need to collaborate with global IT vendors who are knowledgeable, cost-effective and prompt in service.

Aging workforce and change management:

Operations in the steel industry require deep domain understanding and factors such as layout, unit sizes, product types, raw material sources, market dynamics and automation level influence associated business processes. Situation demands more agile, tech-savvy teams who can quickly gather domain knowledge and contribute towards incremental transformations. A global IT partner can attract, deploy, enable and nurture the right competencies to align with the organization’s larger goals.

Phased Approach to Outsourcing

Steel companies need to assess outsourcing initiatives right from when they are conceptualized and work out the financial implications. Their assessment may need to be validated by key stakeholders and/or external experts. After such an assessment, a global IT firm can be recognized as a partner.

Global outsourcing involves large scale changes within an organization as it could involve multiple geographies. The scope may be limited to only enterprise applications and/or to complete manufacturing IT systems and plant-level automations. The nature of outsourcing can be application development and maintenance on a large scale with a focus on incremental transformation.

Here are a few steps to make such a venture successful:

Optimize existing IT workforce

The existing IT team should be assessed on team strength in different competency areas based on the target load. Essential strategic key resources should be retained and those which can fulfill future IT requirements can be tapped.

Choice of outsourcing

Complexity of systems and severity of impact on disruption pose a major challenge to global IT outsourcing. Enterprise business systems control only business functions. These systems have, therefore, less impact on day-to-day manufacturing. Manufacturing Enterprise System and the automation layers therein have a direct influence on manufacturing. This necessitates steel companies to outsource enterprise business IT first, followed by manufacturing IT.

Benefits of IT Outsourcing

IT outsourcing would allow steel companies to free-up some operational budgets and help transform business faster by implementing new IT initiatives through global partners. Some of the benefits of IT outsourcing in steel industry are: