The manufacturing industry is in the midst of a major transition. Industry 4.0 manufacturing is all about leveraging advanced technology to connect and automate every facet of the manufacturing process. Connecting floor machinery, equipment, and the end product with IoT sensors to the company’s networks via the cloud creates a smart factory that allows both manufacturers and customers to gain more useful insights.

Manufacturers that have implemented these types of smart factory initiatives have seen 10-12% gains in output, factory utilization, and labor productivity, according to Deloitte. But Industry 4.0 manufacturing technologies offer more than internal efficiencies. They also allow manufacturers to see what happens externally with the products they build. Cloud infrastructure and cloud-based applications will grow by 2022 at a rate of 150% or more, according to IDC. Comparatively, traditional software will grow at a rate of 11%.

Today, manufacturers must focus on servitization, the innovative approach that puts the focus not on the product but on a combination of product-centric services. These services ensure that the product’s outcome is continuous. In other words, it means selling an outcome rather than a product.

Through the cloud, the end products can report how they are being used and whether they need to be fixed. These services can not only help manufacturers adjust the products that have yet to be released, but also offer something to the current customer through servitization of manufacturing. The cloud and IoT have greatly increased the visibility of what happens to the products once they leave the shelves.

The technological capabilities made possible by Industry 4.0 create an enhanced feedback loop. The product sends feedback to the manufacturing network as needed to report on its own functionality. Then data analytics processing can alert people to the need for the product to be serviced. This connected product can even be serviced remotely.

But that shouldn’t be the end of your feedback loop. If the product’s data uncovers a malfunction within the manufacturing process, it should be fixed immediately on the production line. The data could also signal how customers actually use the product, which could lead to manufacturing adjustments, optimizing user experience in real time.

The platforms that manage IoT solutions are inherently distributed due to the existence of a vastly diverse range of devices. Such devices carry certain limitations in terms of energy and processing capacity, as well as low storage capacity. The technical specifications involve managing and discovering IoT devices, handling (acquiring and analyzing) received data, and generating events or alerts from the IoT data. Quality of service (QoS) of these platforms has a direct impact on servitization. Factors that decide QoS are scalability, real time, timeliness, availability, reliability, security, and reusability.

The Revolutionary Benefits of the Servitization Model

Considering the potential of servitization of manufacturing, it is here to stay. Servitization fits so well with Industry 4.0 initiatives that PricewaterhouseCoopers reports 78% of U.K. manufacturers are developing servitization models that focus on customer relationships and aiding customer retention.

Servitization opportunities don’t end with the consumer feedback loop. The data you’re collecting will allow the manufacturing company to build a robust data management framework that will act as the foundation for new opportunities. Here are three more interesting opportunities manufacturers should consider as they implement a servitization model:

1. Data discovery as a service

Data is becoming an integral part of manufacturing. In recent years, tech implementations in factories have allowed more data to be collected than ever before, but now manufacturers are collecting and sorting data sets that lead to insights, expertise, and excellent service in Industry 4.0 manufacturing.

The insights garnered from the data can help manufacturers locate equipment that needs service before it causes a problem in the production line. This predictive maintenance data can keep companies’ equipment running efficiently internally. The data collected from the purchased products can keep them a step ahead of the service needs externally and internally to make any necessary product adjustments.

One of the largest industrial manufacturing companies in Europe uses data insights on rail-mounted airport luggage carts to evade costly penalties and improve the overall user experience. Acoustic and vibration data on the carts allows them to predict when carts will require maintenance, avoiding cart breakdowns that will hold up the luggage transfer process. Data has led to these invaluable insights that weren’t achievable until now, putting the manufacturing industry in a unique position to chase efficiency at every turn.

Scalability is important to maintaining quality of service, and microservices-based architecture patterns play a large role. This architecture outlines the distribution of the applications in a set of services so that each is independent of another.

These applications produce and process exponential volumes of data. Because of this, organizations might become overwhelmed. A technique called data scaling is vital to managing, storing, and processing the deluge. That way, scalable data platforms can accommodate rapid changes in the growth of data, in either traffic or volume. These platforms utilize added hardware or software to increase output and storage. Without data scaling, it will be hard to grow with your application infrastructure.

2. Service innovation and monetization

Servitization offers manufacturing companies a new service line and revenue channel that will truly surprise and delight customers and allow manufacturers to differentiate themselves among their peers. What does this look like? A leading manufacturer and service provider of aero engines offers its airline customers a total-care package for gas turbines based on a fixed-dollar, per-flying-hour price scheme. Similarly, a large American corporation that sells print and digital document products and services now sells customers “pay-per-page” service packages that uses predictive analytics and data monitoring to improve efficiency.

When you begin offering the servitization model to customers, consider what basic operating services you can provide, then ladder up with value-added services that might include leasing, technical services, or outcome-based support. Customers might pay in a subscription-based model based on product uptime, not just a one-time payment.

This servitization model also gives products a longer lifetime, which results in less waste, maintaining a greener business model that will delight customers. This is especially true for larger products such as automobiles and machinery.

Most of these servitization models use a server-less approach in which the product owner allows users to execute portions of code called “functions” without having to take care of the infrastructure. Acting as the service provider, the product owner is responsible for transparency and access based on demand. The owner can therefore define restrictions and implement a payment model for the resources.

3. Creating a knowledge-centric culture

All of this data collection will enable powerful information governance, allowing manufacturers to achieve more transparency in their collaborative relationships. Blockchain and the cloud remove unnecessary bottlenecks and keep all of that shared information in one spot.

This will help manufacturing companies foster a knowledge-centric relationship with their vendors that will lead to increased efficiency in time and lowered cost of operations. This isn’t just good for the manufacturer, but for everyone’s bottom lines.

A leading independent provider of packaging products and services uses real-time data insights to provide peace of mind and transparency to its customers. The manufacturer offers a remote asset-monitoring element to its service, allowing customers to virtually track the security of their products through transport. Customers can receive data on the location, humidity levels, and jostling of their products — providing a more holistically transparent and reassuring experience for the customer.

Product-service system (PSS) is a special case of servitization in which systems of products, services, supporting networks, and infrastructure are designed to be competitive, satisfy customers’ needs, and have a lower environmental impact than traditional business models. In PSS business models, industries develop products with value-added services — instead of a single product — and provide their customers with core services that are needed for the business. In this relationship, the market goal of manufacturers is not one-time product selling but continuous profit from customers by total service solution, which can satisfy unmet customer needs.

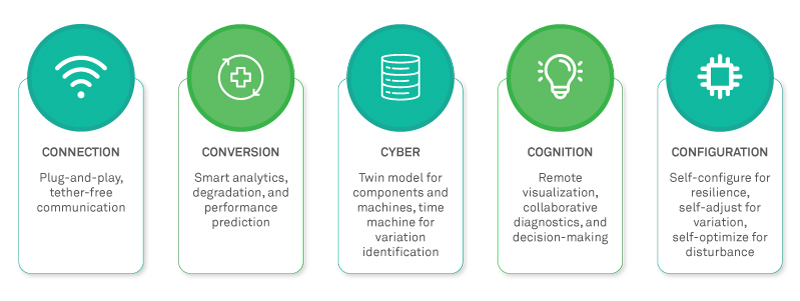

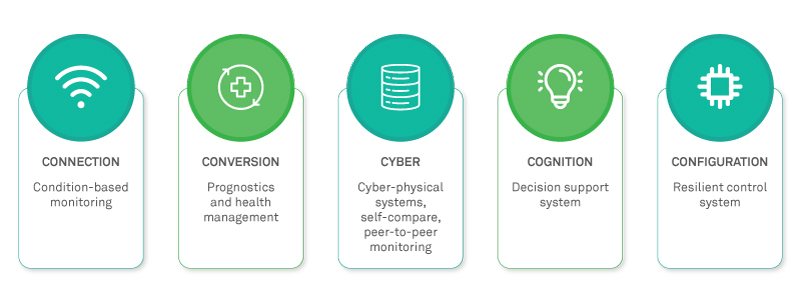

With advanced smart analytics, cloud computing, and a cyber-physical systems (CPS) framework, industries will be able to achieve a fleetwide information system that helps machines be self-aware and actively prevent potential performance issues. Smart analytics for achieving such intelligence will be used at the individual machine and fleet levels.

The 5 Cs of the Architecture Model in Cyber-Physical Systems

Integrating CPS with production, logistics, and services into the current industrial practices would transform today’s factories into an Industry 4.0 factory with significant economic potential.

Servitization of manufacturing is the direct result of better data collection and data sharing, all capabilities ushered into the manufacturing industry by the Fourth Industrial Revolution. Don’t get left behind; embrace the technology.

Vinay Firake

Senior Vice President & Head - Manufacturing (Europe), Wipro Ltd.

Vinay heads the manufacturing business for Europe at Wipro. He has more than 25 years of diverse experience across business development, consulting, professional and outsourced services, operations and finance. Over the past two decades at Wipro, Vinay has assumed various leadership roles across the U.K., Benelux, Nordics, DACH, France, Rest of Europe, and the U.S. In his most recent role, he was the Global Head for the Enterprise Digital Operations & Platforms business, which spans across the Communications, Consumer, ENU, Manufacturing, Technology, and Health SBUs. Follow him on LinkedIn.