The energy industry is undergoing a tectonic shift as the world is focusing on increased use of renewables, and de-carbonization of the economy, by shifting the energy supply chain from molecules to electrons. Such a shift will require a number of years as the existing energy systems are hardwired to exploit the usage of hydrocarbons. Energy demand and prices continue to fluctuate due to external factors such as geo-political tensions, pandemics etc. During this period, National Oil Companies are focused on fast monetization of their reserves, by increasing the rate of extraction and capturing market share. Integrated Oil and Gas companies’ focus would be to diversify as well as continue to extract hydrocarbons safely and securely while reducing costs and improving productivity and efficiency across the entire energy value chain.

The Oil and Gas industry has been a pioneer in the adoption and deployment of technology. The industry deployed sensors to measure various process parameters such as temperature, pressure, flow etc. from its assets, captured and processed the information in real-time to identify any anomalies, and used the information for decision-making and operational reporting. The deployment of these technologies was limited to critical assets and processes owing to the cost of connectivity, reliability as well as maintainability.

The last couple of decades have witnessed an exponential advancement in technology owing to its adoption in the consumer domain, be it IoT, Cloud computing, Analytics or AI/ML. Sensors got built into mobile phones and wearables, deployed in automobiles and at homes, which are always on and connected, storing and transmitting data to the cloud to process it and derive insights, and to provide value to the individual as well as leverage new business opportunities. Seamless, ubiquitous, low-cost network connectivity along with adequate bandwidth have been key enablers for such advancement and widespread adoption. Over the past few years, the Oil and Gas industry has been progressively adopting developments in such technologies from the consumer domain and applying them to an industrial context. Oil and Gas assets, being remote and in harsh environments, have always struggled with secure, reliable, low latency network connectivity. Challenges in ubiquitous network connectivity have also constrained deployment of these technologies such as wireless sensors/IoT, ability to process data in near real-time and derive insights that can be used for decision-making at the assets and/or remote offices.

Some of the challenges that Oil and Gas companies face include:

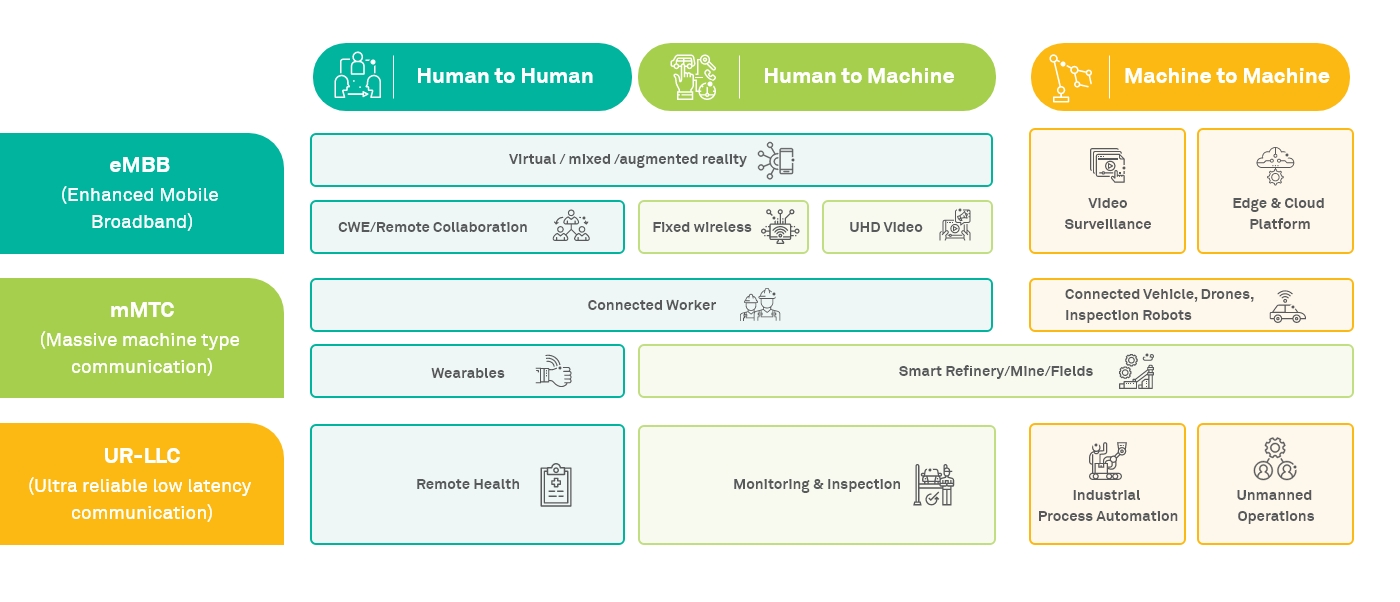

Developments in 5G technology, and the market opportunities that 5G provides different service providers, have the potential to address a number of challenges that Oil and Gas organizations are facing, while embarking on Digitalizing their asset-centric operations. 5G technology addresses the following broad level of use cases:

Enhanced Mobile Broadband (eMBB) – While aimed at entertainment such as video social networking and multimedia communications with higher resolution video channels, it has immense potential in the O&G industry, especially to adopt video-based surveillance in asset operations.

Massive Machine Type Communications (mMTC) - Designed for wide area coverage for hundreds of thousands of devices per square kilometre, typically to ensure ubiquitous connectivity for cheap, basic software and hardware units with minimal energy consumption, e.g. to monitor a city’s air quality, gas emissions, etc.

Ultra reliable low latency communication (UL-LLC) - For monitoring and control in real time, with very low end-to-end latency and high reliability. Aimed at industrial workflows such as the automation of energy distribution in a smart grid, in industrial process control and sensor networking where there are stringent requirements in terms of reliability and low latency.

Given the technology advancements in 5G, Oil and Gas Organizations will keenly monitor market developments, deployment and availability of 5G network services for their remote assets. The ability of telecom service providers to deliver 5G services (public 5G) at remote locations where Oil and Gas organizations need it may take time and may not be of high priority for them. 5G technology has provisions for organizations such as Oil and Gas companies or Oil Field Service companies to set up private 5G to address the network & connectivity challenges faced at the remote assets. These companies can also sell 5G network services to other organizations including telecom service providers to deliver 5G services at the remote assets when the need arises. The technology also helps to dynamically change the Quality of Service depending upon the use case as well as the situation at the asset to prioritize the traffic between corporate data services, voice & video, Alarms/Events etc. & land/mobile radio. Though this capability existed in the earlier technology, it was managed by the network/telecom service provider. With private 5G, it can be better controlled and managed based on the specific requirements at the remote assets.

Opportunity canvas of applying 5G technology in the Oil & Gas Industry is depicted below:

While several of these opportunities are not new and unique, and have been implemented in a few assets, widespread adoption was mainly hampered due to a lack of seamless, reliable and secure connectivity, low cost wireless sensors (at times that needed to be custom developed for a specific asset) and adequate data processing capability at the remote assets. Given the improvement in networking technology that 5G is able to deliver, adoption of 5G would be a key enabler to accelerate adoption of a number of these use cases at the remote Oil and Gas assets.

High-impact use cases that would significantly benefit from the adoption of 5G technology are summarized below:Video Surveillance complemented by advanced analytics and ML can improve operational efficiency as well as health and safety. Cameras can be mounted in strategic locations or videos can be captured from drones or unmanned autonomous vehicles. Apart from the visible light spectrum, videos from special cameras can capture images that can be processed to detect gas leaks, measure corrosion and inspect assets to prevent any unplanned shutdowns. Videos can also be analyzed in real-time for health and safety such as personal protection equipment compliance, drowsiness/distraction detection, etc. Effective realization of video surveillance requires high bandwidth and low latency networks to capture and transmit the data to local systems at the assets for processing and analyzing the data in real-time and generating alerts.

Reliable and ubiquitous network connectivity enables the adoption of Connected Worker paradigm. These could be for Digitization of Maintenance & Inspection forms through guided workflows using Head Mounted Displays and Voice commands, simplifying the information capture (through images/videos) for audit and compliance purposes or enabling the Remote worker to collaborate with Experts who are based in office while undertaking any maintenance/inspection activity.

Deployment of a large number of low-powered wireless sensors to capture and transmit data in real-time over secure, reliable, low-latency high-bandwidth 5G network provides the ability to increase automation through exception-based surveillance, adoption of predictive analytics for critical as well as non-critical assets etc. It also provides the opportunity to further enhance the efficiency of industrial processes through the use of software agents & robots, and automate a number of operator tasks at the remote assets.

Given the immense potential of 5G technology, Oil & Gas organizations will need to prioritize where 5G technology should be deployed, based on the lifespan of their assets, and whether they should adopt Public 5G or Private 5G. The realization of the benefits of 5G technology will require collaboration with other initiatives in the organization such as investments in adopting IoT, Advanced Analytics and automation.

Ravindra Balija has 25 years of IT experience and has been working with Energy and Utilities customers for the last 18 years. He currently focuses on how emerging technologies and the Wipro CTO Themes can be applied in the Energy Industry for digital transformation. He is passionate about distributed and decentralized technologies such as Cloud, IoT and Blockchain to help Energy and Utilities customers with Energy Transition.

He can be reached at: ravindra.balija@wipro.com