Cognitive and Predictive Mining: Improving Efficiency and Driving Capabilities

Mining has become an increasingly precise practice. Modern mines have applications that ship and synthesize data from a variety of sources resulting in accurate mine planning, scheduling, operations and transportation. Data flows in from diggers, grinders, concentra-tors and trucks. In conjunction with data from enterprise systems, miners are able to make sophisti-cated forecasts. They know that a pump will fail in exactly 3 months, a truck’s bearings will need replacement in 2 weeks or an electric rope excavator will stop.

Cognitive computing and predictive analytics together with machine learning technologies are poised to heighten the levels of accuracy and preciseness in operational areas. These are the technologies to put on your must-watch list.

Let’s briefly consider a scenario which mining experts suspect leads to inefficiencies and bottlenecks, but unfortunately have little or no control over. This scenario concerns the operators of functioning within the next 5 shifts. It is relatively easy to continue to make improvements around the edges of available data and reap incremental benefits. However, with the technology available today, it is possible to stretch the horizons of intelligent mining beyond the existing paradigm. As an example, cognitive computing and predictive technology can accurately tell us where to dig, how much to dig and where the ore should be shipped for blend-ing in order to meet contracts or take advantage of a sudden spike in prices.

big excavator equipment. These are large and expensive machines – so expensive that mining operations cannot afford to have standby excavators. They need to operate at maximum efficiency with minimal downtime. While machine performance data can predict when an excavator is likely to fail, there is no accurate way to measure poor operator performance during a given shift and neutralize it so that production is not affected.

It is entirely possible that an operator is in a portion of the mine where the geology is highly variable and the excavator is loading the incorrect material onto a truck. This is not necessarily a fault of the operator. It is a professional hazard. Is there a way to alert the operator inside the cab and direct the operator’s attention to the correct material? In other words, can we augment the operator’s skill, experience, knowledge and judgment and dial up the levels of performance to absolute maximum?

A peek into the future

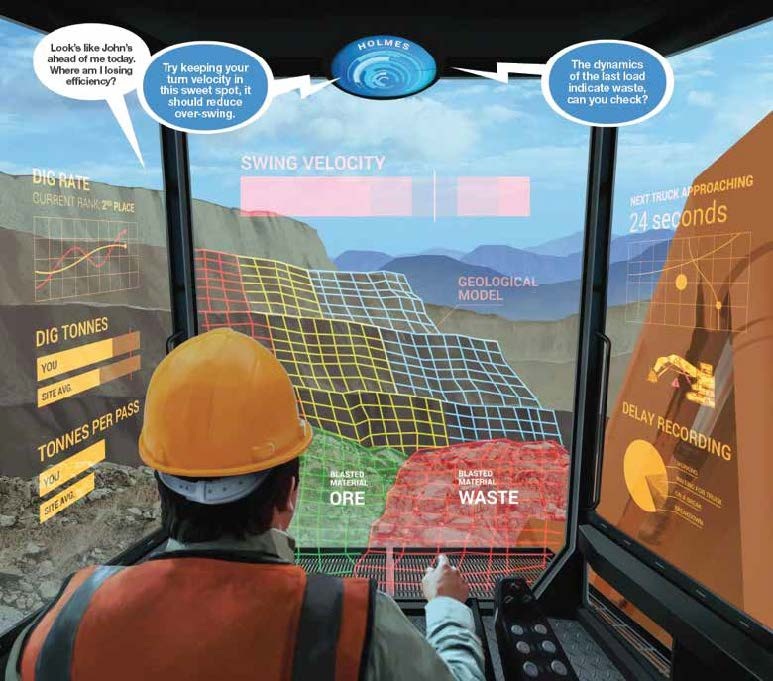

As it turns out, we can. A modern mine operation that uses an Artificial Intelligence platform that can be ‘plugged in” to its total environment can provide digital assistance to the operator. The system inside the cab could listen to the operator using a natural speech algorithm and maps this against actions of the excavator. The system would learn with every action and iteration. The system would also use the vast array of sensors on the equipment to provide real-time feedback and guidance to the operator so that they can adjust their actions and get better performance.

Geological information could be displayed on the cab window as a HUD or a Heads-Up-Display (see Figure 1: Augmenting Operator Skills, Experience and Judgement Using Cognitive and Machine Learning Technology). The simple-to-follow graphic rep-resentation of the mine ensures the operator knows where to dig for maximum efficiency.

Figure 1: Augmenting Operator Skills, Experience a

Learnings from other industries

Now let’s move this scenario up by one level. Imagine for a moment that the cognitive system in the cab has access to operational informa-tion about the excavator. The system is capable of monitoring and mapping, say, the swing of the excavator arm against optimal metrics. The system automatically alerts the operator every time there is an over-swing, informing the operator of the exact loss in productivity, “ Harry, that continual over-swing cost us 3% in produc-tivity last shift. Need a visualization to control the arm accurately for the next pass?” Harry, our opera-tor, can see (on the HUD) that he is falling behind on his shift objec-tives and immediately takes corrective action prescribed by the advanced on-board system.

From here it is a simple step to gamifying the cab and delivering motivational data to Harry. A dash-board inside the cab can potential display not just Harry’s target productivity, but that of other oper-ators in the shift (“Harry, John in Digger 17 in the East End of the pit is ahead by 10 points”). The leader-board can inject some fun and games into achieving improved performance and, more important-ly, motivate operators to enhance their skills using technology as a coach.

At Wipro we have been leading the way with cognitive computing, predictive analytics and machine learning across a variety of indus-tries ranging from financial servic-es to oil & gas and for horizontal processes such as help desk support. These are labor-intensive industries and practices where the pressure for urgent intervention to bump up the accuracy of process-es and boost productivity is high. We believe there are several learn-ings from these industries that can be applied to mining:

Cognitive computing and predic-tive analytics are going to lead the future of mining. These technologies will not only address productivity, but elevate human, asset and environmental safety to previously unattainable levels. At the moment, the logic and reasons to assess these technologies is exciting and spells a considerably improved future.