Rapid escalation of the current worldwide healthcare crisis is posing unprecedented challenges in terms of availability of life-saving medical devices. There is an urgent demand for increased supply for life-saving equipment such as Ventilators, N95 Masks, and Protective Gloves & Gowns along with various tools & devices used in manufacturing these medical devices. While Medical Device manufacturers, globally, are working hard to increase their manufacturing output, they are challenged by a number of constraints in their supply chain. To bridge this demand-supply gap, Non-Medical Device manufacturers such as Automotive, Apparel and Industrial Manufacturing companies can collaborate with Medical Device manufacturers and Open Source Community to adapt and augment production of these equipment, leveraging their own network of manufacturing capacity and supply chain.

We see three categories of players that are key to addressing the current situation and all of them have certain challenges and opportunities.

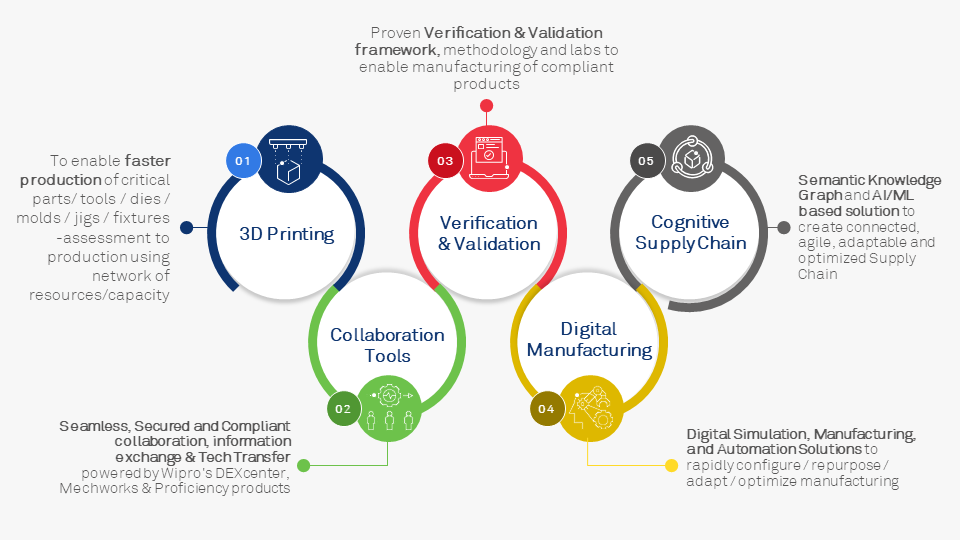

The following key capabilities across the product value chain are needed by Non-Medical Device Manufacturers to achieve this objective:

Wipro’s Accelerated Adaptive Manufacturing Framework

Wipro, using its Accelerated Adaptive Manufacturing Framework, can leverage its extensive experience, ready-to-use solutions and partner ecosystem to enable faster technology transfer and accelerate manufacturing of urgent life-saving equipment working in tandem with both Medical and Non-Medical Device Manufacturers; this on top of Wipro’s Cognitive Supply Chain Brain shall tackle all the Data Management Challenges in a Distributed, Extended and Connected Enterprise.

Wipro’s deep Product and Industry Knowledge of over 35+ years in the Medical Equipment/Device Engineering space, powered by a Large, Diverse and Global Talent Pool of 20,000+ engineers (which is fully enabled for remote contribution and collaboration) has been instrumental in providing the desired expertise/experience in our Customers’ engineering journey.

Wipro’s Industrial & Engineering Services

Wipro’s Industrial & Engineering Services (IES) is the driver for our Engineering Services portfolio with 4 decades of proven experience. IES facilitates over 500 clients across multiple industries / verticals with a platform to innovate and engineer products, platforms and technologies at scale. This platform of services offerings combines the maturity of engineering processes, the passion for latest technology and access to a diverse ecosystem to deliver value to customers at various stages of the product or platform life cycle. This is termed as “Engineering NXT” by Wipro. With 400+ patents, Engineering NXT has delivered 5,000+ products across a wide portfolio including VLSI and system design, Software, Wireless, Data platforms, IoT, Industry 4.0, well supported by a 20,000+ strong Engineering community.

Sankar Natarajan, a part of Wipro’s Industrial & Engineering Services, heads Digital Product Value Chain and PLM Consulting Practice.

Girish Datar, a part of Wipro’s Industrial & Engineering Services, heads Industry 4.0 Consulting Practice.

Ajay Sinha, a part of Wipro’s Industrial & Engineering Services, heads the Engineering Design Services Consulting Practice.

To know more download our report here