It has often been a journey rife with technology buzzwords, to catch up with the latest trend, but most enterprises have not been able to scale up and create value out of their I4.0 forays. The balance and focus has been difficult to achieve, while on one hand you want to extract the best out of your already existing last-generation CapEx, on the other, trying to optimize the OpEx without investing significantly on making the existing CapEx latest. There is a need for a comprehensive and scalable methodology that can guide enterprises in their Industry 4.0 journey. Wipro’s SDI Framework defines a smart, digital, and intelligent way for enterprises to look at Industry 4.0 initiatives across industries, incorporating the latest in technology and processes to create value.

Why are enterprises not getting value out of Industry 4.0?

The Industry 4.0 paradigm is making enterprises rethink on how they respond to stay relevant and competitive. Enterprises are trying to re-invent business models, going from a product-based to an outcome-based or servitization-oriented model while simultaneously trying to optimize cost and efficiency. In the #newnormal, post pandemic, while the need for Industry 4.0 is gaining more steam, the perennial issue of not being able to successfully scale up is slowing the growth.

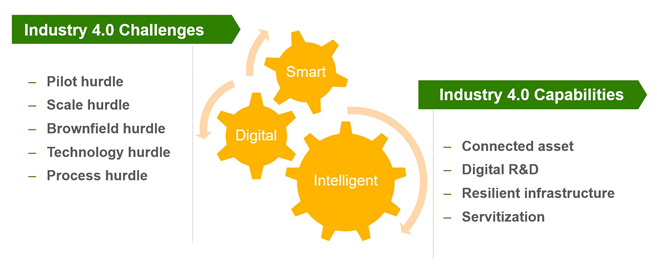

Scaling is necessary for getting value out of Industry 4.0. Getting a few PoCs right sporadically will not help to create value. It is like managing a small locality or neighborhood versus managing a countrywide program. Challenges and opportunities at scale are different and need to be planned and executed differently for the desired outcome. These are specific challenges enterprises face while scaling up Industry 4.0 programs:

In summary, traditional siloed technology approaches at a limited scale ignoring the challenges of extracting efficiency in brownfield scenarios and integrating with processes is inhibiting value creation in Industry 4.0.

Smart, Digital, Intelligent (SDI) is the way forward to create value in Industry 4.0

Enterprises are finding themselves in a challenging situation where though Industry 4.0 potential looks promising, the current approach and outcomes are not instilling confidence. The boundaries of existing enterprise architecture and a piecemeal approach limit the scaling of Industry 4.0 initiatives. The enterprise architecture needs to be relooked along with the exponential technological advances to make it decision-oriented and market-facing. Apart from leveraging technological advances, enterprises need a scalable way to transform their enterprise architecture and facilitate Industry 4.0 initiatives.

The challenges discussed in scaling Industry 4.0 initiatives can be solved by SDI to create desired capabilities, as shown in exhibit 1.

Exhibit 1: Smart, Digital, Intelligent (SDI) Solving Industry 4.0 Challenges and Creating Positive Outcomes

SDI methodology is about making the entire digital thread from “source to design to build to make to consume” synchronous in addressing the economics of the value chain. Beyond economics, all of these moves are aimed at one another important thing - making the enterprise’s transition from real-time/experiential systems to cognitive-based systems.

SDI methodology can create tangible desired outcomes of efficiency, flexibility, productivity, and quality. For the delivery of any outcome, there must be an augmentation of capabilities. SDI augments the following capabilities:

Wipro implements SDI with a comprehensive and scalable framework across industries

The biggest piece of the puzzle is how enterprises can implement the smart, digital, and intelligent way for getting value out of Industry 4.0 initiatives. Wipro has developed a comprehensive SDI Framework to help enterprises in their Industry 4.0 journey. Wipro does it flexibly and cost-effectively in a methodical fashion. Industry 4.0 is a long-term journey; a marathon where enterprises can start small but the direction and path to value should be clear.

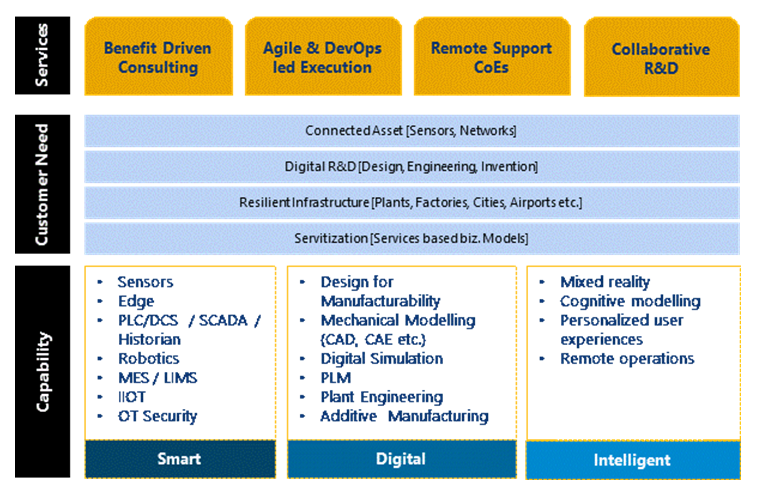

The key components of the SDI Framework are:

The details of the SDI Offering Framework are shown in Exhibit 2.

Exhibit 2: SDI Offering Framework

SDI is creating value and helping enterprise transformation in many industries. The common thread across industries is increasing digital acceleration, unlocking and analyzing data, and increasing investment in AI/ ML capabilities. These benefits alone should be a strong reason for enterprises to adopt SDI. Some specific SDI examples across industries are:

Bottom Line: Enterprise needs a compass to navigate their Industry 4.0 journey. SDI can guide enterprises for scalability and value creation in Industry 4.0

Every business is aspiring to deliver connected experiences, streamline operations, quickly launch new products and services, and personalize customer service. Industry 4.0 promises to deliver this. But changing enterprise architecture with Industry 4.0 is a marathon and not a sprint. It requires futuristic planning and relentless execution. SDI can enable an enterprise to start their Industry 4.0 journey today, and help at every step until they scale up and realize value. The ease of scaling is significantly addressed by SDI, where the timeline is reduced by about 50% over conventional methodologies. Benefit-driven consulting ensures that there is stepwise ROI delivered within a conceivable time frame of 3 to 4 quarters and not in the distant future.

SDI is like having a compass on a long, fruitful, and transformational journey that guides enterprises and helps them stay on course. Needless to say, enterprises that develop and follow their Industry 4.0 compass will outpace their peers who don’t!

Pareekh Jain

Pareekh Jain is the Founder and Lead Analyst of EIIRTrend and Pareekh Consulting.

A seasoned professional with 20+ years of experience, Pareekh has seen the engineering and manufacturing industry from four perspectives: service provider, sourcing advisor, enterprise buyer, and industry analyst. Pareekh’s expertise is in providing actionable insights by analyzing market trends.

He is regularly quoted in the media on engineering services, IoT, and outsourcing trends, including Harvard Business Review (HBR), NDTV, Times of India, Economic Times, Business Standard, Hindu, Business Line, Livemint, Financial Express, and Business Insider.

Pareekh is a thought leader, having authored various publications on topics related to engineering, IoT, and Industry 4.0. He received his MBA from the Indian Institute of Management (IIM), Bangalore, and his Bachelor of Technology degree from the Indian Institute of Technology (IIT) Delhi.

He can be reached at pareekh@pareekh.com. Follow him on twitter @pareekhjain.

Asish Adhikari

General Manager, I4.0 Strategist, Industrial & Engineering Services, Wipro Ltd.

Asish is a Digital Transformation Evangelist in the field of I4.0 with 20+ years of experience. He spent the initial years of his career in the O&G domain, in the areas of pre-commissioning, commissioning, operations & planning functions. Asish has been a Research Associate with IIT Bombay, in the field of Optimization & Simulation, working with leading Process Licensor UOP. He played a pivotal role in shaping and incubating the engineering business of TCS throughout his six-year stint with them. Before joining Wipro, he spent almost 10 years with Invensys / Schneider Electric, heading their Industry Solutions for O&G, Power. He also architected GTM policies for APAC & ME for leading Product portfolio in the Operations, Design & Simulation space.

LinkedIn page – https://www.linkedin.com/in/asishadhikari