How a port-handling equipment manufacturer reduced cost by using Wipro ITI’s LIMM solution

Client Background

Our client is the second largest Asia-Pacific developer and manufacturer of port-handling equipment with 11 joint-operating plants. Their main products are portal cranes, bulk ship loaders and unloaders, floating cranes, and large-sized overhead cranes. Their customers are located throughout the Pacific Rim and North America.

Industry Landscape

With increasing seaborne trade across the globe, the port equipment market is expected to grow from a $6.5 billion-dollar industry to a $9 billion-dollar industry by 2025[1].With rising trade activities, vessel size and cargo volume are increasing, resulting in an increased strain on ship berths and shipyards. Ports are incorporating smart solutions to optimize operations, reduce logistics costs, and enhance efficiency. Increasing awareness regarding carbon footprint and inclination toward environmentally friendly transportation will contribute to port equipment market growth. Government regulation limiting carbon emission from port equipment is leading to the adoption of equipment that utilizes alternative fuel.

The industry leader is dominant and able to deliver on very aggressive schedules while smaller, leaner competitors dominate on price. Increased competition and market dominance by the largest producer of port equipment mandates the rapid introduction of more product types to grow sales revenue, increase net income, and increase R&D investment. The future income growth rate will be through new products and services with services providing the highest level of ROI. Cost reduction will focus primarily on materials costs. Consequently, the ability to decrease time to market, reduce cost, and enable a lean product development process is critical to increase market share. Product development processes and technology improvements like LIMM help overcome current barriers.

The Opportunity

The client receives a request for proposal, product requirements, and regulations as explicit documents and/or links to specific regional or wharf-specific applications. The client is given 21 calendar days to prepare engineering concept drawings, provide a fixed price quote, and schedule for delivery. The process is to select a previous design that closely matches the requirements for the new design, quickly run reports based on the existing design BOM to obtain the required cost data from recent purchases. Two-dimensional drawings are manually edited (text changes only) to characterize the product based on new requirements.

The data is packaged, an executive review is conducted, and the numbers finalized based on shipping, installation, insurance, and profit. Final numbers were reviewed by the company president and head of sales for final refinement. The result of this process caused several strategic issues:

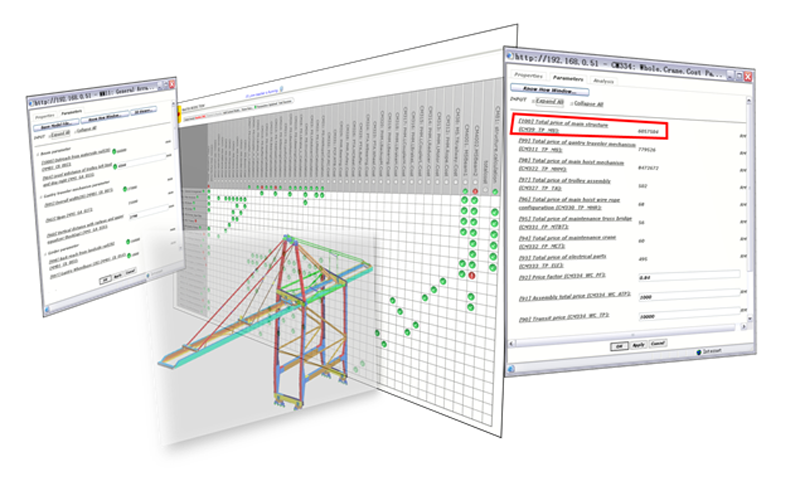

The client was looking for a solution that would provide a rapid and efficient product development process that enabled a proposal’s cost to be based on the design. The client asked for quick results and decided on an incremental deployment where each increment was a different product line. The first product line selected is the container crane that is used to load and unload ships. The container crane product line consists of 48 structural configurations and each of these is configured based on other functional requirements and wharf loading limits. The goals of the project included moving the design into 3D, using the geometry to drive engineering analysis, material estimates, and BOM pricing. The objective was to generate a quote based on the design, refine the design, and review cost multiple times during the 21-day window; then delivery is based on the design for which the quotation is submitted.

Solution

The client chose ITI as a strategic partner for the deployment of a new product development process and technologies. Qualifying criteria included proven process consulting expertise, specifically in product development, and a proven technology base to support information integration.

Business Impact

The client has realized significant benefits from the implementation of the solution by ITI

The benefits of such a system included decreased time and effort to produce accurate quotations that match product engineering, reduced material cost, improved business “win rate”, and eliminated project financial losses due to underestimating manufacturing costs.

References:

[1] https://www.gminsights.com/industry-analysis/port-equipment-market

Rendell Hughes

Director of Advanced Manufacturing Solutions, Wipro ITI

Rendell is the Director of Advanced Manufacturing Solutions at Wipro ITI. He is a mechanical engineer with experience in the aerospace industry having worked at General Dynamics and Lockheed. His tenure at ITI has included managing the development of ITI software products; consulting in automotive, consumer electronics, and heavy equipment industries; and managing projects and technologies for the US Air Force, Navy, and Army. The advanced manufacturing solutions are based on a foundation of hyper-automation, multi-experience, and democratization of technologies. Rendell can be reached at rendell.hughes@iti-global.com.