What is Digital Twin?

Digital Twin, as a concept, has been around for a while. There are several use cases for which Digital Twin can be applied. As a concept, Digital Twin has been widely accepted as a virtual representation of a physical asset, which could help in getting data using IoT sensors from across all the physical devices. The IoT data can then map their process and activities in a virtual world, thanks to the world of sensors and PLC and what not, we are able to realize all the physical assets. The new dimension of thinking is whether we can apply this concept for testing our applications. Probably one the best reasons why Gartner repeatedly rates Digital twin as one of the Top 10 technologies for 3 years now.

Why Digital Twin for Testing

There are two types of Digital Twin

Process Twin:

Product Twin:

In the current scenario of development of a product towards business users, there is no way we can test with the real-time business scenario. All testing depends on manipulated data and there is no way we are able to realize the sequence of activities that happen in a production environment. It is also impossible to test the whole scenario with all the data and application interactions the way it happens in production. The current process lacks a snapshot of the production data that helps in retrieving and replicating the way scenarios panned out. There is no mechanism to slow down or speed up the data entry and attempt the same scenarios in a faster input manner. Soak a test environment with the same data sequentially and repeat the same activity multiple times, and this reduces the testing efficiency overall.

The Innovative Way of Testing and Enhancing Application Behavior

With the above scenario as a problem statement, what if we can build a system that can virtualize, visualize and test the application all in one go? In a real-time scenario, this would be extremely advantageous for any business owner because now he not only visualizes the process but also is capable of effectively testing the application that is behind the system.

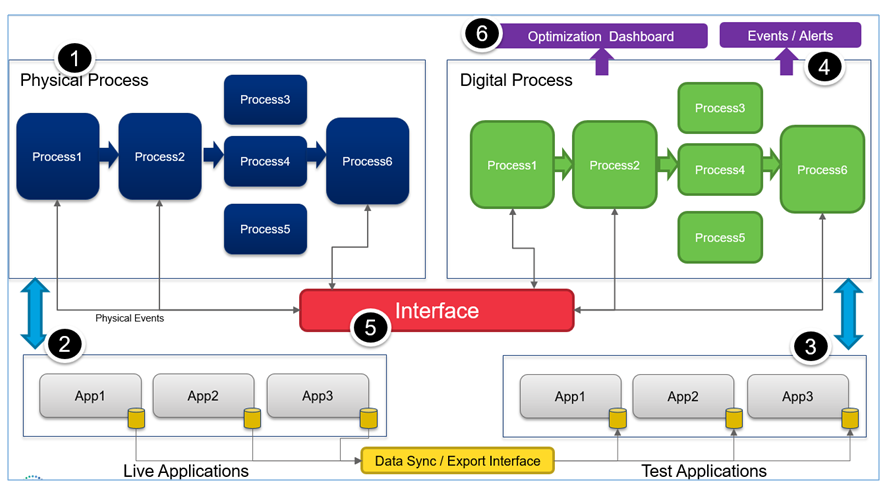

Fig1: Digital twin Architecture for application testing

A Process twin becomes very effective in case of a testing world. The process needs to happen in 4 steps, namely:

Gathering of production data is done by ways of attaching all the physical events as they happen in the production to the interface as well as attaching the data synch to the live applications and capturing the real-time data events as they happen

With the live data events captured, the physical events’ and the live applications’ feed of data sync are exported, and the sequencing is then done based on time and event ID. Triggered events are aligned and the overall process of the activities that happened in the application are determined.

The Digital process is now made to exactly replicate the production physical process by recreating the conditions as they happened. This activity ensures the test application and the live application are in real-time sync, and the twin is connected continuously and is picking up event data as they happen.

Now the near real time data can be sequenced and the test application can be tested with production data and production triggers. Any failure that had happened in production can be replicated easily in test system and application testing accuracy improves significantly. With the new process of testing setup, this will change the way testing is ever done.

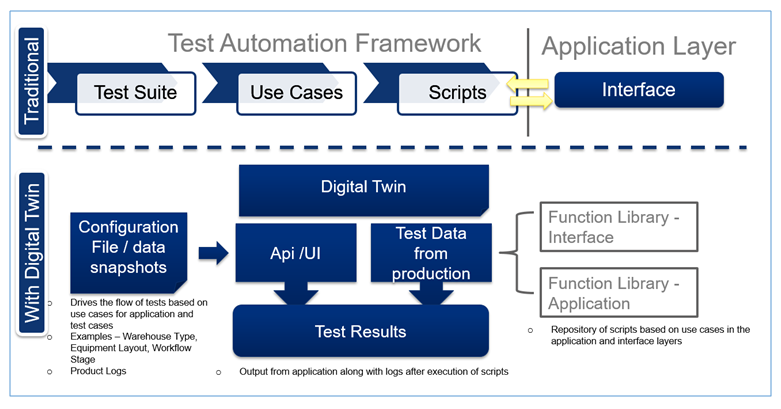

Fig2: Test Automation and application testing process using Digital Twin

Test events that have been captured can now be used for analytics and can drive efficiency, predict and even prevent failures from happening.

Conclusion:

Testing is one of the most important and critical activities that happens before every application rollout and gives a lot of sleepless nights to business users, IT professionals and Developers. With the advancement and enhancement of using the new way of testing, failures that happen in production systems can be foreseen and can be predicted and also prevented. In today’s world of testing, this is also possible but will be very costly. With the Digital Twin’s introduction, it purely becomes a simulated testing and any test condition, and prod location can be brought to life in a virtual world. With near real-time data and test conditions, no failure shall escape the watchful eyes of Digital Twin Testing.

Venkat Jayaraman

Distinguished Member of Technical Staff, Solution Architect Digital Twin

Venkat is a Distinguished Member of Technical Staff and Head of Pre Sales for EMEA for the Industrial Engineering Team. He is a technologist with over 38 patents to his credit. He had architected the Digital twin testing concept and had successfully implemented the same. With close to 20 years of industry experience, his expertise has enabled the success of Digital twin testing.

Kavitha Gopalakrishnan

Subject Matter Expert - Digital Twin Virtualization

Kavitha is a Senior Consultant and the SME of Digital Twin virtualized testing for the Industrial Engineering Team. She is an expert in virtualization and implementation of Digital twin across multiple industries. With close to 15 years of industry experience, her expertise has tremendously helped in making the Digital twin testing a success story.