Modern manufacturers already faced many challenges – intense competition, evolving customer expectations, demand variability, inventory proliferation, and stringent regulations. During the past 18 months, they’ve added one more to that list: the risks associated with unplanned catastrophes and black swans. Effective inventory management, a robust supply chain, and smart inventory planning are no longer necessary simply to survive in a complex environment. The pandemic has shown that they also provide a critical foundation for their adaptable and resilient future. These issues are driving the urgency for digital transformation and Industry 4.0.

The Industry 4.0 Vision

Industry 4.0 goes beyond smart manufacturing. Done well, it combines physical production and operations with smart digital technology, machine learning, and big data. The ultimate aim is to create a holistic and connected ecosystem that focuses on optimizing value across manufacturing and supply chains. The complex but digitized operating model enables companies to stay connected with real-time insights into customers, products, competitors, and the overall business climate.

SAP’s strategy for Industry 4.0 is more than smart manufacturing in factories and plants. It is connecting production with processes across the supply chain. Industry 4.Now is SAP’s strategic investment to help customers transform the manufacturing business and become future ready. It’s a vision for more unique and disruptive outcomes spanning various industry verticals. SAP’s Industry 4.Now revolves around four themes: Intelligent Products, Intelligent Assets, Intelligent Factories, and Empowered People.

Multi Echelon Inventory Optimization for Smarter Planning

Conventionally, spare parts planning is done through various software applications in an isolated manner. The critical machine level nuances and inputs are not modeled as part of the problem. This delivers siloed planning recommendations like safety stock norms that may not be pragmatic to implement and still need significant manual intervention. An approach is needed that addresses this gap to make spare parts an integral component of the connected network (an intelligent asset network) within the principles of Industry 4.0.

Intelligent assets can be leveraged along with integrated business planning to deliver optimized industrial replaceable items using the Multi Echelon Inventory Optimization (MEIO) capabilities of SAP IBP. This approach enables modeling of MEIO for spare parts to calculate the recommended safety stock. MEIO helps organizations optimize inventory levels across distribution networks with multi-echelon planning – even in a global organization. A MEIO solution suggests the right levels of inventory at each stage of the supply chain by simultaneously optimizing inventory across multiple echelons and locations.

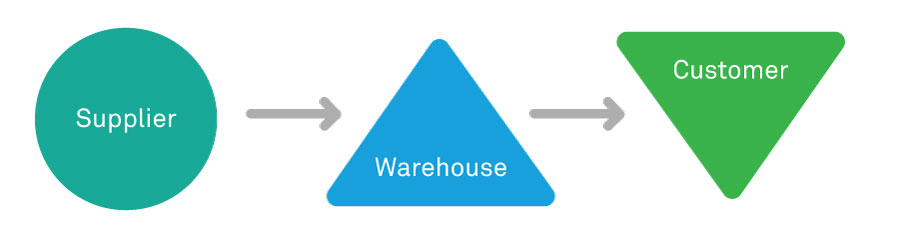

For the multi-echelon algorithm to work effectively within the SAP IBP application, there are three critical parameters: service level, lead-time variability, and demand variability. Figure 1 provides a quick overview of the MEIO model that can compute safety stocks as one of its critical outputs after optimization. A supplier node is connected with the warehouse, which in turn is integrated with the customer node (or customer facing node) in a supply network.

Figure 1: MEIO model

The complexity of planning inventories for replaceable industry items include: quantity of safety stock with associated costs; cost of industrial equipment failure; how the stocking nodes are designed; cost of redundancy and obsolescence; and other dependencies such as OEM dealers, lead times, etc.

Reimagining the MEIO Model

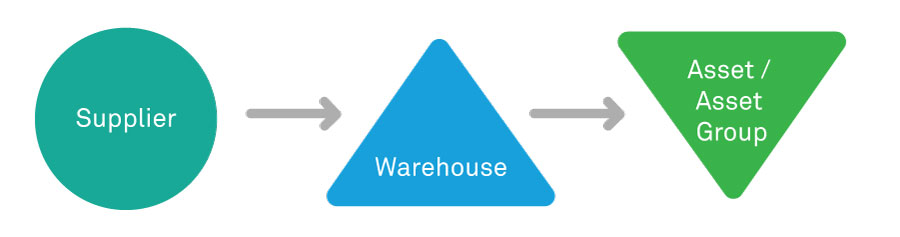

Now, re-imagine the same multi-echelon model by replacing the customer node with equipment. The equipment can be a single asset or group of assets that act as the “customer” in the re-imagined multi-echelon model. Again, the challenge is to compute the service level associated with each replaceable item for the equipment or asset group. Leveraging the Industry 4.0 paradigm, the intelligent asset network using IoT sensor data can be translated as an equipment service-level factor, which is a key ingredient for MEIO. In effect, it means a health check of equipment, with data provided by the IoT sensors.

Figure 2: Re-Imagined MEIO model

The re-imagining of the conventional multi-echelon into asset based MEIO improves the accuracy of the replaceable safety stock calculation by reducing the uncertainty of critical resource downtimes. This is done by computing the relevant safety stock planning of spares in an interconnected asset framework. Crafting the scenarios associated with various aspects of safety stock planning can be designed using SAP IBP application.

Leverage Templates for Further Gains with MEIO

Wipro has designed specific scenarios relevant to the replacement industrial items business model using IBP. These scenarios leverage the capabilities of the re-imagined MEIO to reduce inventory costs and improve service levels. The ready-made templates expedite demand planning by leveraging this SAP IBP model solution and can be implemented 20% faster than normal implementation timeframes. For organizations with complex inventory supply chains, the MEIO model provides greater visibility, resulting in improved demand planning, reduced costs across the supply chain, and streamlined operations. MEIO takes a step further towards optimizing service levels while minimizing inventory costs.

Chandramohan Muthuvaradharajan

Managing Consultant and Senior Supply Chain Solution Architect, Wipro

Chandra has over 20 years of global experience successfully transforming supply chains with SAP APO, SAP SNC, SAP S/4 HANA & IBP product applications. He currently leads the SAP Digital Supply Chain Planning solutions for the consumer packaged goods (CPG), high tech, and manufacturing industries. Chandra is also the Product Owner for Wipro’s application monitor for complex process chains to deliver planning solutions into auto pilot mode.