Introduction

It was one of those hectic Monday mornings when Jeremy was rushing to work for a client meeting and his car broke down on the freeway. Helpless and exasperated, he managed to somehow get help to tow the car to the nearest service center. Jeremy was running against time and was completely thrown off the gear as service representatives were unable to give him any clarity on the fixes needed and the repair cost, not to mention the long queue of cars ahead of him.

For a “digital-age” customer like Jeremy, this was an experience that left much to be desired. In this age of fast-paced technological transformations, consumer behavior is increasingly influenced by the digital experiences offered by the brands they choose. However, customer experience in the automotive repair segment has not evolved to keep pace with the needs of the “digitally tuned” customers. Providing such digital experiences to customers like Jeremy mandates that there be models that can transcend traditional automotive maintenance and provide seamless connected services.

‘Bay’ Watch

For the US automotive repair market that is fast-paced, over-served and under-differentiated, customer engagement holds the key. From issues related to services bays to feedback mechanisms, there are challenges aplenty.

Poor Asset Utilization

Repeat Jobs

Cost and Time Gaps

The Silver Lining

The current value delivery model needs to be upended to offer better cost and quality of service. Information visibility across the value chain will be a key enabler for this purpose. Connected Automotive Maintenance offers this capability by gleaning information from the running vehicle and linking the vehicle to the cloud of backend systems.

Prognosis/Diagnosis

Intelligent cloud-based platforms analyse the vehicle data vis-à-vis vehicle history and rules database to build preliminary diagnosis. This automated diagnosis with suggested solution can be augmented by human experts to give a time/cost estimate and, thus, provide upfront information on the repairs. Over time, same system can leverage analytics to derive insights and alert the customer of upcoming issues so that such car breakdowns can be avoided altogether.

Technician-free Resolution

Some problems can be resolved through push of secure over-the-air updates to the vehicle. For the do-it-yourself (DIY) enthusiasts, OEMs can leverage e-commerce portals for parts sale and create Augmented Reality-based mobile applications for user support. This will drastically reduce customer visits to the service center.

Connected Maintenance

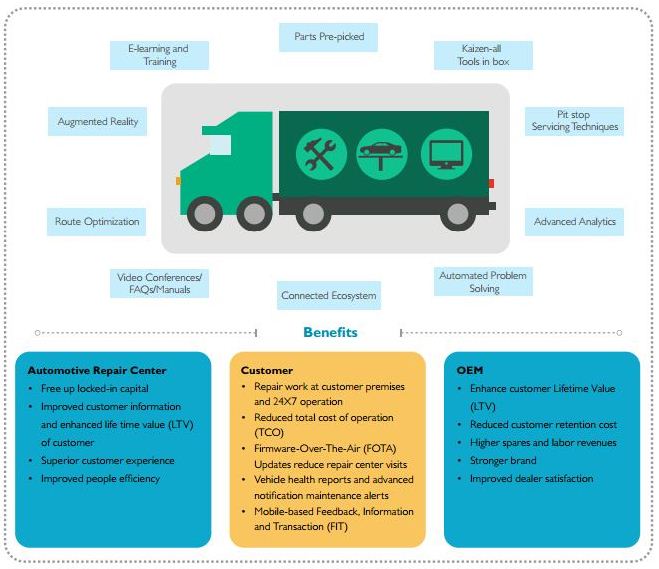

Most of the automotive repairs do not require large infrastructure and can actually be accomplished at customer premises. Figure 1 illustrates the key aspects of this.

Features of Connected Automotive Maintenance Van

Once customers like Jeremy report the issue through a mobile application, an automated diagnosis system looks through the vehicle history, current health and builds a repair job plan. For parts replacement, the warranty of the identified components is checked and claim is processed.

An analytics of historical warranties and parts sales help build a stock plan for the parts. Post that, the customer is notified and an appointment is scheduled at the desired location (home/work) through a mobile app. Then, a service van with compact facilities and cross-skilled personnel is dispatched to the location.

Service technicians employ Kaizen and Kanban who approache wherein pre-picked tools and parts are kept in a convenient layout for quick and smooth service. Augmented reality-based tools guide the repair process and reduce the risk of job failure. Technicians clarify doubts in complicated jobs through video conference with experts housed at a central hub. Post repair, the customer inspects the vehicle and pays through a mobile application.

A tailored, end-to-end approach will digitally transform the automotive service center, benefit customers like Jeremy and OEMs in multiple ways.

For Automotive Service Centers, progression from the current “asset-heavy legacy infrastructure” to “asset-light and resource-heavy setup” will free up locked-in capital and minimize fixed costs substantially. A connected ecosystem will improve the repair job visibility, leading to improved resource utilization and customer experience. For Customers, repair work at the customer premises, in reduced time and at lower cost of repair is bound to heighten the comfort factor. For OEMs, the benefits will reflect in greater loyalty, which will result in reduced customer retention cost, higher Life Time Value (LTV) and a stronger brand.

Anupam Bhattacharjee

Anupam Bhattacharjee is the Head of Auto domain in Wipro, where he leads the Automotive Centre of Excellence and digital solutions for the auto, aero and defense verticals. He has over 16 years of experience in sales strategy, innovation, channel sales, institutional sales, product management, service/spare parts and dealer development in two of India’s largest automobile companies. Anupam did his engineering from Jadavpur University, Kolkata, and has a Masters in Management from Loyola College, Chennai. He does research on electric vehicles and had represented India in the Global Forum of Electric Mobility in Rio+20, organized by the United Nations

Amit Holey

Amit Holey is a Principal Consultant for Wipro’s Automotive business. He has handled project implementations, solution designs and has played a key role in project analysis, proactive domain proposals and sales. He has experience in design and execution of small to large programs across Sales, Marketing and After Market segments for Automotive OEMs across geographies. Amit holds a Master of Information Technology from Virginia Tech, USA, and a Post Graduate Diploma in Systems Management from S.P. Jain Institute of Management & Research, Mumbai.