The Six Sigma methodology is not new - it has been around since the 80s. What is interesting is its long shelf life. It continues to be relevant to modern day operations despite rapid technological advancements. A data-driven approach, it helps reduce defects in products and services, while increasing customer satisfaction through continuous process improvement1 2. As the key focus of Six Sigma is process improvement, organizations can apply Six Sigma principles across various initiatives and activities, including data science, business intelligence (BI) systems and data quality. Every process has one or more independent input factors f(Xs) that are transformed by a function to produce an output. Six Sigma is calculated as Y = f(x) + Ɛ where ‘Y’ is the desired outcome or the result of the process which depends on the f(Xs). Here Ɛ represents the error factor or how accurately the f(Xs) are transformed, to create the outcome.

To ensure accurate results using the Six Sigma formula, it is important to focus on the causes, i.e. the f(Xs) and not on the result ‘Y’. By identifying causes and negating them, users can automatically improve the result as the objective of Six Sigma is to improve process performance by reducing variance. The more variation a process has, the lower will be the quality of the output. However, to achieve process improvement breakthroughs, it is critical to minimize the input variable variance in order to minimize the output variable variance.

Marrying Six Sigma and analytics for optimal process performance

Let’s take a deep dive into how Six Sigma and analytics work together to improve quality outcomes in the age of Machine Learning (ML) and Artificial Intelligence (AI).

Measuring phase: The first step is to determine data quality for accuracy and precision, and clean it for further use. In a typical scenario, governed data quality initiatives are conducted at a global or regional level, as opposed to specific analytics projects.3 The next step involves descriptive analytics that answers the question “What happened?” This step explores the data to visualize and understand what the data is saying. To do this, we use the Y = f(X) + Ɛ equation.

Analyzing phase: Once users understand the variables and features, it is easy to diagnose factors and root causes that affect the problem outcome. The variables are represented as the Xs in the Y = f(X) + Ɛ. equation. Often, in ML, the number of features can be reduced without affecting the result through the analyzing phase of Six Sigma.

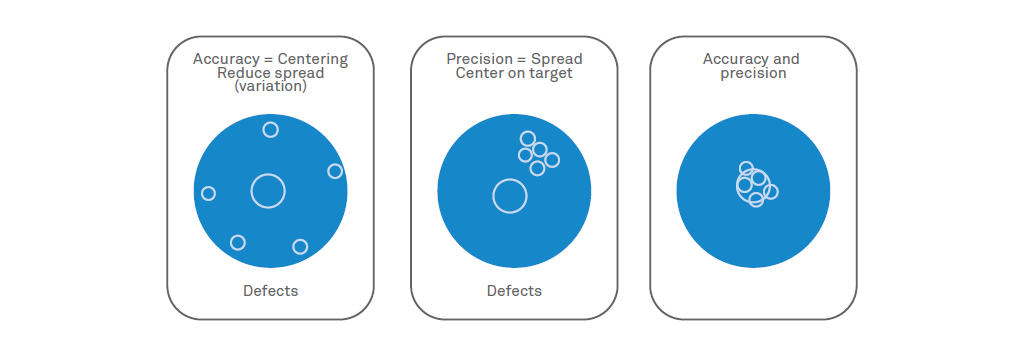

The next step in the process involves using predictive and prescriptive analytics to answer questions such as “What could happen?” and “What should we do?” For successful results, it is important to select the right models and conduct several experiments to determine which model produces the best results. When applied to ML, Six Sigma ensures that a process reaches its target with accuracy (centering), and precision (spread) for optimal and sustainable process performance. For example, in the game of archery, if a target is reached without variance control (the spread around the target), there is no guarantee that the shots will be centered. However, if variance is reduced, it will result in a much tighter cluster (see figure.1).

Figure 1: Using the example of archery to understand how SS contributes to Machine Learning

It is only by consistently hitting the center and keeping the variance small that one can improve performance. In archery, the wrong stance, an inconsistent anchor point or lack of sight adjustment, can result in poor performance. Similarly, in an ML model, reduction in Six Sigma variance can improve the accuracy of supervised and unsupervised ML models. Processes contain variance because of bias and normal randomness. So it follows that if input variables or factors have variance, the output will also have variance. The result: inaccurate ML models.

It is important to note here that ML data cleansing is not the same as Six Sigma variance reduction.

In Six Sigma, users analyze the business process to find the source of variance in the input variables and reduce the variance or eliminate the bias. In ML, users do not analyze the business process. Instead, they only correct the data or eliminate the data that does not make sense. But data cleansing does not actually reduce variance. This means that if variance is not well understood, the ML model will not perform well.

For example, in Figure 2 the chart on the left represents data after it is cleaned while the chart on the right represents data after variance reduction. It is clear that after variance reduction, the ML model results are much more accurate.

Figure 2: The process of Six Sigma variance reduction

In essence, data cleaning needs to include variance reduction of Six Sigma for an accurate, reliable, and effective ML model, be it a supervised or an unsupervised learning model.

Leveraging the power of Six Sigma and analytics in healthcare

Six Sigma is especially beneficial for processes that manage, collect and analyze massive sets of data. For instance, in healthcare, the massive sets of data include patient records, doctor’s visits, medications prescribed, and other treatment procedures.4 5 The data also includes information on patient wait time, down time of diagnostic equipment, and the time spent by staff on medical procedures and paperwork.

Organizations can collect data at every step of a process, and through analytics, find the root causes that impede the delivery of a product or service and determine variance, or eliminate unnecessary steps in the process. Predictive analytics can also be used to search for hidden trends in historical data, and relationships between dependent and independent variables. For example, an ML model can analyze and predict when surgical equipment need replacement, how many people visit a healthcare clinic each day, the type of treatment prescribed, and the average wait time.

The Winship Cancer Institute, for instance, used Six Sigma and predictive modeling, to reduce wait time from about one hour to less than 15 minutes.6 By looking at the predictive model in 15-minute increments, they are able to staff the Institute with the required number of healthcare professionals, at the right time.

Six Sigma and analytics join forces to boost business predictability

Even with constant technological advancements, the core principles of Six Sigma continue to make an impact on businesses across industries. Analytics coupled with Six Sigma helps build a process-focused business that can rapidly meet changing market demands. It is only by gaining predictability that an organization can maintain processes that achieve real and measurable results, that meet and exceed customer demands.

Reference

1 https://businessjargons.com/six-sigma.html

2 https://www.sixsigma-institute.org/What_Is_The_Focus_Of_Six_Sigma.php

5 https://www.sixsigmadaily.com/combining-lean-six-sigma-big-data-healthcare/

6 https://www.sixsigmadaily.com/combining-lean-six-sigma-big-data-healthcare/

Stephen C. Folkerts

Consulting Partner, Data, Analytics and AI, Wipro Ltd.

Stephen is an Information Management and Governance leader with over 30 years of experience in Business, Application, and Information Architecture. Included are Metadata Management, Data Quality Management, Data Integration, Master Data Management, Business Intelligence and Analytics.

His experience spans the following verticals – Pharma and Life Sciences, Hospitality, Media, Tax, Audit and Advisory.